|

Packaging 473 ml

|

Wynn's Valve Injector Cleaner is professionally formulated to safely clean intake valves, fuel injectors and combustion chambers. Wynn's Valve Injector Cleaner is formulated and packaged for use in the Wynn's Enviropurge Fuel Injection System Cleaning Apparatus (Part No. 04000). Wynn's has long expounded the economy and performance benefits of a well maintained vehicle. Now we add environmental responsibility to the list of reasons for keeping vehicles in top operating condition. The delivery system for Wynn's Valve Injector Cleaner - Wynn's Enviropurge, is an easy to use, safe and effective service solution to fuel system contamination issues in modern, engine management controlled

vehicles.

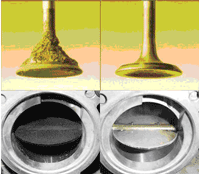

Deposit Problems

Wynn's Valve Injector Cleaner (and Wynn's Throttle Body Cleaner) are designed to overcome vehicle deposit problems encountered with today's fuel injected engines operating on unleaded fuel. Engine design changes for better efficiency and lower emissions coupled with typical non-metallic octane enhancers used in unleaded fuel (e.g. olefins, polynuclear aromatics, oxygenates, etc.) lead to increased propensity to form deposits on intake valves, fuel injectors, combustion chambers, and air intake systems.

Combustion chamber deposits increase a vehicle's octane requirement. Higher octane unleaded fuels use PNA's, olefins, and/or oxygenates to achieve higher octane values. However, these same components lead to more combustion chamber deposits, and the engines appetite for octane increases further. Octane Requirement Increase (ORI) leads to annoying knocking and pinging (which can cause damage to cylinder heads in extreme situations) and reduced power on demand, particularly in vehicles equipped with knock-sensors that retard spark timing upon sensing knock. Fuel injector flow problems from deposits lead to uneven distribution of fuel and overall performance deteriorates. This has been a field problem since the mid- 1980's. This combination of fuel system deposits causes poor driveability, hesitation, stalling, reduced power, poor fuel economy, and poor overall performance. If a regular engine tune-up is performed without addressing fuel system deposits, the customer may not be satisfied with the maintenance performed.

World-wide field experience with Wynn's Valve Injector Cleaner (and Wynn's Throttle Body Cleaner) strongly indicates that its use, either in conjunction with a regular engine tune-up or on its own, provides a significant difference in vehicle performance that the customer can feel, and greatly enhances customer satisfaction with the workshop service performed.

Wynn's Valve Injector Cleaner (and Wynn's Throttle Body Cleaner) are chemical kits for professional installer use, to remove and dissolve fuel system deposits found on:

intake valves;

fuel injectors;

air intake systems;

manifolds;

combustion chambers;

and throttle bodies.

Wynn's Valve Injector Cleaner (and Wynn's Throttle Body Cleaner) can be used either in conjunction with regularly scheduled engine tune ups, or on its own, to restore fuel system-related vehicle driveability performance, power and acceleration performance, low emissions, optimal fuel economy, and lower octane requirement to improve customer satisfaction.

Advantages

Wynn's Valve Injector Cleaner is a super concentrated mixture of organic cleaning solvents, detergents, lubricating oils, rust inhibitors and other components that will clean deposits on fuel injectors, intake valves and combustion chambers. Wynn's Valve Injector Cleaner restores lost power, improves fuel economy, and reduces exhaust emissions.

Key BenefitsWynn's Valve Injector Cleaner is professionally formulated to provide the following benefits:

- Cleans intake valves, fuel injectors, and combustion chambers.

- Restores lost power and fuel economy.

- Lubricates and conditions fuel systems.

- Protects against rust and corrosion.

- EPA Registered in U.S.A.

- Restores engine "breathing".

- Eliminates engine surging, stalling and hesitation.

- Improves air flow for smoother idling.

- Stops engine knock and run-on.

- Reduces exhaust emissions and octane requirements

- Safe for oxygen sensors and catalytic converters

Technical Data

| Appearance |

Appearance |

| Colour (Visual) |

Amber |

| Colour |

0.5 (ASTM D 1500) |

| Density @ 15°C |

0.828 (ASTM D 4052) |

| Flash Point (°C) PMCC |

9 (ASTM D93) |

| Boiling Point (°C) |

82-149 |

| Volatiles (% Vol) |

89.3 |

| pH (Concentrate) |

10.0 (ASTM D 1287) |

| pH(5% mass in Distilled Water) |

9.2 (ASTM D 1287) |

|

Materials Safety Data Sheet

Wynn's Professional Products Valve Injector

Combustion Chamber Cleaner (V.I.C.) |

WYNN'S

A division of Illinois Tool Works Inc.

1151 West Fifth Street

Azusa, California 91702

|

EMERGENCY TELEPHONE NUMBER:

Chemtrec (800) 424-9300

INFORMATION TELEPHONE NUMBER:

Wynn's (626) 334-0231

|

|

PRODUCT IDENTIFICATION

| PRODUCT NAME | EFFECTIVE DATE | PRODUCT CODE |

| Wynn's Professional Products Valve Injector Combustion Chamber Cleaner (V.I.C.) | 12-30-05 | 61510, 61517 |

| CHEMICAL NAME | | CAS NUMBER |

| N/A | | N/A |

HAZARDOUS INGREDIENTS

| COMMON NAME | CHEMICAL NAME | CAS NO. | OSHA PEL | ACGIH TLV-TWA |

| Xylene | Mixed Xylenes | 1330-20-7 | 100 ppm | 100 ppm |

| Ethyl benzene | Phenylethane | 100-41-4 | 100 ppm | 100 ppm |

| Petroleum Hydrocarbon | Solvent Naphtha Light Aromatic | 64742-47-8 | None Established | None Established |

| Isopropanol | 2-Propanol | 67-63-0 | 400 ppm | 400 ppm |

Contains no other ingredients now known to be hazardous as defined by OSHA 29CFR 1910.1000(z) and 29CFR 1910.1200.

PHYSICAL DATA

These data are approximate or typical values and should not be used as precise specifications. Unless otherwise noted values are at 20°C(68°F) and 760 mmHg (1 atm).

| Boiling Point/Range |

180-300°F(121-232°C) |

Freeze Point |

N/D |

| Specific Gravity (H20=1) @ 15.6°C |

0.83 |

Vapor Pressure (mm Hg) |

>1 |

| Vapor Density (Air =1) |

>1 |

Solubility in Water (%) |

Disperses |

| % Volatiles by Volume (CARB) |

N/D |

Evaporation Rate (Butyl Acetate = 1) |

> 1 |

| pH (as is) |

N/A |

pH (dilute) @ 5 % |

N/A |

| Appearance |

Clear amber liquid |

Odor |

Aromatic Solvent |

N/D - Not Determined

< = Less Than

N/A - Not Applicable

> = Greater Than

FIRE AND EXPLOSION HAZARD DATA

Flash Point: 61°F(16°C) Method Pensky-Martens ASTM D-93

Flammable or Explosive Limits (Approximate percent by volume in air)

Lower (LEL) N/D Upper (UEL) N/D

Hazard Class Identification

Flammability 3

Health 2

Reactivity 0

Other -

Hazard Code

0 - Least (insignificant)

1 - Slight

2 - Moderate

3 - High

4 - Extreme

Extinguishing Media

Carbon dioxide, dry chemicals, foam, water fog.

Special Fire Fighting Procedures

Use water to cool fire exposed containers. Fire fighters wear a self-contained breathing apparatus.

Unusual Fire and Explosion Hazards

DO NOT spray near open flames.

REACTIVITY DATA

Stability

Stable.

Conditions to Avoid

Heat, open flame.

Materials to Avoid

Strong acids and oxidizing agents.

Hazardous Decomposition or Combustion Products

Thermal decomposition will produce smoke, oxides of carbon, and nitrogen.

Hazardous Polymerization (conditions)

Will not occur.

HEALTH HAZARDS/ROUTES OF ENTRY

Signs, Symptoms and Effects of Overexposure

Ingestion (swallowing) May be harmful or fatal if swallowed. Due to its low viscosity, it may enter lungs during

swallowing or vomiting. Once in lungs serious damage may occur.

Skin Contact Irritant to skin. Can cause defatting of skin, redness, dryness, cracking of skin.

Prolonged and repeated contact can cause moderate skin irritation, defatting of skin,

dermatitis. Can absorb through skin, on prolonged contact.

Eye Contact rritant to eyes. Will cause burning of eyes, blurred vision, watery eyes.

Inhalation (breathing) Vapors are harmful if inhaled. Irritant to upper respiratory tract. May cause dizziness,

nausea, headaches.

Other Effects of Prolonged/Repeated Overexposure

This product contains trace chemicals that have been identified as a carcinogen by NTP,

IARC or OSHA. Vapors in a confined area in high concentrations are anesthetic.

Overexposure may result in light headiness, dizziness, nausea. Chronic Effect:

Prolonged and repeated over-exposure to solvents may result in brain and nervous

system damage. May cause kidney and liver damage. This product contains chemicals

known to the State of California to cause cancer and birth defects or other reproductive

harm.

EMERGENCY AND FIRST AID PROCEDURES

Ingestion (swallowing) DO NOT induce vomiting. Call a physician immediately.

Skin Contact ash affected area with soap and water. Remove contaminated clothing.

Eye Contact Flush with water for 15 minutes. If irritation persists, call a physician immediately.

Inhalation (breathing) Remove person to fresh air to avoid further inhalation.

Comments NOTE TO PHYSICIANS: Ingestion or subsequent vomiting can result in aspiration of light

hydrocarbon liquid into the lungs, which can cause pneumonitis.

SPILL OR RELEASE CONTROL PROCEDURES

Steps to be taken in case material is released or spilled

Eliminate all sources of ignition. Isolate and contain material, restrict entry to area. Insure adequate ventilation

and absorb with appropriate inert materials. Use non-sparking tools. Place absorbed material into waste

containers.

Waste Disposal Method

Dispose of in accordance with Federal, State and Local regulations.

EPA Reportable Quantity (RQ), 40CFR302 (CERCLA104)

Xylene (100 lbs.), Ethyl benzene (1,000 lbs.)

EPA Toxic Chemical Release Reporting, 40CFR372(SARA313)

| Chemical | CAS NO. | % in Product |

| Xylene | 1330-20-7 | 30-40 |

| Ethyl benzene | 100-41-4 | 30-40 |

HANDLING AND STORAGE

Handling and Storage Precautions

Danger: Flammable liquid. Keep away from heat and flame. Vapors harmful. Contains xylene and isopropanol.

Store away from heat, flame spark. Avoid breathing of vapors. Use adequate ventilation.

Other Precautions

Eye wash station.

PERSONAL PROTECTION - EXPOSURE CONTROL

Ventilation

Provide explosion proof local exhaust to keep exposure concentrations below TLV & LEL limits.

Respiratory Protection

If vapors exceed TLV/PEL values, use a NIOSH approved respirator.

Eye Protection

Safety glasses with side-shields.

Protective Gloves

Impervious gloves.

Other Protective Clothing or Equipment

None special.

Work/Hygienic Practices

Personal cleanliness is always appropriate. Frequent washing minimizes chances of inadvertent exposure.

TRANSPORTATION INFORMATION

Department of Transportation (DOT) Classification

| | Flammable Liquid | | Corrosive |

| | Flammable Solid | | Non Flammable Gas |

| | Flammable Gas | | Non Hazardous by DOT |

| | Combustible Liquid | | Other |

DOT Proper Shipping Name

Flammable liquids, N.O.S. (Xylene, Isopropanol).

DOT ID Number

UN 1993

PACKAGING GROUP

II

Note: Consumer Commodity, ORM-D may be used for ground transportation within the USA for cases of 61510, 61517.

DOCUMENTATION

Product Code No.: 61510, 61517

Previous Code No.: 61510, 61517

Issue Date: 12-30-05

Prior Date: 08-17-05

This information is, to the best of our knowledge and belief, accurate and reliable as of the date compiled. However, no

representation, warranty or guarantee is made as to its accuracy, reliability or completeness. It is the user's responsibility

to satisfy himself as to the suitability and completeness of such information for his own particular use.

|

|

|

|