|

Wynn’s Diesel InjectorFormulated to:

- Clean diesel fuel systems including injectors and combustion chambers.

- Restore proper injector spray pattern.

- Increase fuel economy.

- Restore overall engine performance.

- Reduce particulate emissions.

- Be used with Wynn's Diesel Clean Machine.

Packaging 473 ml

|

Formulated to:

Formulated to:

- Clean diesel fuel systems including injectors and combustion chambers.

- Restore proper injector spray pattern.

- Increase fuel economy.

- Restore overall engine performance.

- Reduce particulate emissions.

- Be used with Wynn's Diesel Clean Machine.

This product may be used without dilution in any diesel fuel system cleaning equipment.

The Problem

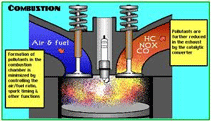

Diesel engines are similar in many ways to gasoline engines. They are both internal combustion engines operating in either 2-stroke or 4-stroke cycles, but they differ in several important ways. Diesel engines use the heat of compression to ignite the air/fuel l mixture , rather than using spark ignition as in gasoline engines. As such, diesel engines rely on very high compression ratios in comparison to gasoline engines, in order to generate the roughly 750ºF (400ºC) temperatures necessary to ignite the fuel upon contact with the compressed and superheated air in the combustion chamber. A diesel engine controls power output by varying the amount of fuel injected into the cylinder, thereby varying the air fuel ratio, rather than by varying or throttling the amount of the air/fuel mixture drawn into the cylinder as in a gasoline engine.

Engine differences, in combination with differences in the fuel, result in diesel engines being much more efficient than gasoline engines, translating to as much as a 40% fuel economy advantage for diesel engines over gasoline engines of the same size. These fuel economy advantages in combination with improvements in combustion processes that have resulted in decreased emissions have greatly increased the popularity of diesel engines in the automotive, light truck and SUV markets. Because of their power output, fuel economy and durability, diesels have always been the engines of choice for the heavy-duty trucking market.

Residues from modern diesel fuels form deposits in the injectors and in the combustion chambers of diesel engines.

Injectors in diesel engines are especially prone to hard deposits because their location exposes them to the high temperatures of combustion. Diesel combustion chamber deposits are similarly hard and difficult to remove. These deposits on the tips of diesel injectors can cause injector sticking or interruption of the normal fuel spray pattern. Such injector and combustion chamber deposits can result in poor performance, decrease d fuel economy and increase demission, specifically particulate emissions. Many products on the market may be “universal” and meant for both gasoline and diesel engines and may not provide sufficient deposit removal to correct performance, fuel economy and emissions concerns.

The Solution

Wynn's® Diesel Injector Purge is a highly concentrated and highly effective product specifically formulated to clean diesel fuel systems, especially the hard to remove injector and combustion chamber deposits. This product is designed to be used with service equipment to completely clean diesel fuel systems, restoring proper injector spray patterns and combustion efficiency to result in increased power, improved fuel economy and reduced emissions.

Wynn's Diesel Injector Purge is formulated for use with Wynn's Diesel Clean Machine, #03500, as directed in the equipment operation manual. This product may also be used with any diesel fuel system cleaning equipment, Provided that the manufacturer's recommendations and operations procedures are followed. This product does not have to be diluted and may be circulated back to the fuel tank and will not harm any fuel system components, including fuel system sensors, filters, catalytic converters, particulate traps and plastic material s such as those sometimes found in injection pumps.

Wynn's Diesel Injector Purge is formulated as the solution for removal of diesel fuel system deposits to restore performance, maximize fuel economy and minimize emissions.

FeaturesFormulated to:

- Clean diesel fuel systems including injectors and combustion chambers.

- Restore proper injector spray pattern.

- Increase fuel economy.

- Restore overall engine performance.

- Reduce particulate emissions.

- Be used with Wynn's Diesel Clean Machine.

|

Materials Safety Data Sheet

DIESEL INJECTOR PURGE

|

|

Wynn's Australia Pty Ltd.

An (ITW), Illinois Tool Works Company .ABN 73 000 370 150

100 Hassall Street, Wetherill Park N.S.W. 2164

Private Bag 35, Wetherill Park DC N.S.W. 2164

|

TELEPHONE NUMBER:

(02) 9828 0900

|

|

PRODUCT IDENTIFICATION

| Product Name | Wynn's Diesel Injector Purge |

| Other Names | 15401 473 ml

Liquid Hydrocarbons / SUSDP Schedule 5

FLAMMABLE LIQUID, N.O.S. / ADG |

| Recommended Use | Cleaning fluid for diesel fuel systems |

| Supplier Name | Wynn's Australia Pty Ltd

An (ITW), Illinois Tool Works Company

ABN 73 000 370 150 |

| Address | 100 Hassall Street, Wetherill Park N.S.W. 2164

Private Bag 35, Wetherill Park DC N.S.W. 2164 |

| Telephone Number | (02) 9828 0900

Email : wynnsaus@wynns.net

Website : www.wynns.net |

| Emergency Phone Number | (02) 9828 0900 Monday-Friday 8.00am - 5.00pm

13 11 26 (24 hours Australia) Poisons Information Centre (PIC)

0800 764 766 (New Zealand) Poisons Information Centre (PIC) |

HAZARDS IDENTIFICATION

| Hazard Classification |

HAZARDOUS SUBSTANCE. NON-DANGEROUS GOODS.

Classified as hazardous according to the criteria of NOHSC.

Not classified as a Dangerous Good according to the criteria of the

ADG Code. |

| Risk Phrase |

R 10 Flammable.

R 37 Irritating to respiratory system.

R 40 Possible risks of irreversible effects. |

| Safety Phrase |

S 2 Keep out of reach of children.

S 24/25 Avoid contact with skin and eyes.

S 36/37 Wear suitable protective clothing and gloves. |

COMPOSITION/INFORMATION ON INGREDIENTS

Pure substances : Not applicable – Mixture

Mixture

| Chemical Identity |

CAS Number |

Proportion |

| Petroleum Distillate |

68476-34-6 |

>60% |

| Diethylene Glycol |

111-46-6 |

10 - < 30% |

| Other non-hazardous ingredients |

- |

< 10% |

| Methyl Amyl Alcohol |

108-11-2 |

< 10% |

FIRST AID MEASURES

| Ingestion |

If swallowed, do NOT induce vomiting. If vomiting occurs, keep

head below hips to help keep liquid from entering the lungs. For

advice, contact a Poisons Information Centre or a doctor. |

| Skin |

If skin or hair contact occurs, remove contaminated clothing and

flush skin and hair with running water. Wash affected area with

soap and water. |

| Eye |

If in eyes, flush with water for 15 minutes. If irritation persists, call

for medical help. |

| Inhalation |

Remove person to fresh air to avoid further inhalation. Apply

artificial respiration if not breathing. |

| First Aid Facilities |

Eye wash station. |

| Advice to Doctor |

Treatment should be controlled by symptoms and clinical conditions. Emesis may be induced under medical supervision. |

FIRE FIGHTING MEASURES

| Suitable Extinguishing Media |

Dry chemicals, carbon dioxide, water spray and foam are

recommended. |

| Hazards From Combustion Products |

Thermal decomposition may produce oxides of carbon, sulphur and

nitrogen. |

| Precautions For Fire Fighters |

Flammable liquid. Avoid heat, flame or other sources of ignition.

Vapours may be ignited by heat or flame. Containers exposed to

heat from fire should be cooled with water to prevent vapour

pressure build up. |

| Special Protective Equipment |

Fire fighters should wear self contained breathing apparatus when

hydrocarbons are involved in fire. |

| Hazchem Code |

3[Y]E |

ACCIDENTAL RELEASE MEASURES

| Emergency Procedures |

Isolate area and restrict entry. Eliminate all sources of ignition. |

| Methods and Materials

for Containment and

Clean Up Procedures |

Use absorbent, sand or clay. Shovel into containers. Remove to

outside. Prevent liquid from entering sewers and water ways.

Dispose of in accordance with Federal, State and Local regulations. |

HANDLING AND STORAGE

| Precautions for Safe Handling |

Keep away from heat and sparks. Do not breathe vapours. Keep

containers closed. Keep out of reach of children. |

| Conditions for Safe Storage |

Provide adequate ventilation. Do not store opened containers. Use

entire contents |

EXPOSURE CONTROLS/PERSONAL PROTECTION

| National Exposure Standards |

| Name |

ES-TWA |

ES-STEL |

ES-Peak |

| None established for product |

- |

- |

- |

| Established for ingredients |

| Mineral Oil Mist |

5 mg/m3 |

10 mg/m3 |

- |

| Methyl Isobutyl Carbinol |

25 ppm 104 mg/m3 |

40 ppm 167 mg/m3 |

- |

|

| Alternative Standards |

Petroleum Oil

Mist OSHA (PEL) 5mg/m3

ACGIH (TLV-TWA) 5mg/m3

Contains no other ingredients now known to be hazardous as

defined by OSHA 29CFR 1910.1000(z) and 29CFR 1910.1200.

Exposure Standard means the average concentration of a particular

substance in the worker’s breathing zone, exposure to which,

according to current knowledge, should not cause adverse health

effects nor cause undue discomfort to nearly all workers.

|

| Biological Limit Values |

No biological limit allocated. |

| Engineering Controls |

Provide adequate general or local ventilation to maintain

concentrations below ES / TLV / PEL limits. |

| Personal Protective Equipment |

| Respiratory Protection |

None required with normal application or use of product. If vapours

exceed ES / TLV / PEL values, use a NIOSH approved respirator. |

| Eye / Face Protection |

Safety glasses. |

| Skin Protection |

Chemical resistant gloves. |

| Thermal Hazards |

None applicable. |

PHYSICAL AND CHEMICAL PROPERTIES

| Appearance |

Clear thin amber liquid |

| Odour |

Petroleum distillate |

| pH Value |

Not applicable |

| Vapour Pressure |

> 1 mm Hg @ 20°C |

| Vapour Density |

> 1 @ 20°C (air = 1) |

| Boiling Point/Range |

137 - 243°C |

| Freezing Point |

Not available |

| Melting Point |

Not applicable |

| Solubility |

Insoluble in water |

| Density |

0.850 @ 15°C |

| Flash Point |

52°C (PMCC) |

| Flammable Limits |

Not available |

| Ignition Temperature |

Not available |

| Volatiles |

5.4% volume |

| Cloud Point |

-3°C |

STABILITY AND REACTIVITY

| Chemical Stability |

Stable |

| Conditions to Avoid |

Heat, flame, or other sources of ignition. |

| Incompatible Materials |

Strong oxidising agents. |

| Hazardous Decomposition Products |

Thermal decomposition may produce oxides of carbon, sulphur and

nitrogen. |

| Hazardous Reactions |

Polymerization will not occur. |

TOXICOLOGICAL INFORMATION

Toxicology Information

This material has not been identified as a carcinogen by NTP, IARC

or OSHA. Chronic exposure may cause kidney and liver damage.

Acute Health Effects

Ingestion

Ingestion of this material may cause vomiting. Aspiration into the

lungs during ingestion or vomiting can result in severe pulmonary

damage.

Inhalation

Inhalation of vapours or mist may cause mild irritation to the upper

respiratory tract. High level exposure may result in central nervous

system depression.

Eye

May cause irritation to eyes.

Skin

May cause irritation to skin. Prolonged or repeated contact can result

in defatting and drying of skin.

Chronic Health Effects

ECOLOGICAL INFORMATION

Ecotoxicity No ecotoxicological classifications.

Persistence/ Degradability Not available.

Mobility Not available.

DISPOSAL CONSIDERATIONS

Disposal Methods

Dispose of waste according to federal, EPA, state and local

regulations. Assure conformity with all applicable regulations.

Special Precautions for Landfill or Incineration

Material suitable for disposal by incineration or landfill through an approved agent.

TRANSPORT INFORMATION

UN Number 1993

Proper Shipping Name FLAMMABLE LIQUID, N.O.S.

Class and Subsidiary 3

Risk.

Packing Group 111

Special Precautions

for User None required.

Hazchem Code 3[Y]E

REGULATORY INFORMATION

Poisons Schedule Liquid Hydrocarbons / Schedule 5 SUSDP No. 21 (2006).

Hazard Category Harmful / NOHSC : 10005 (1999).

FLAMMABLE LIQUID, N.O.S. / ADG Code Sixth Edition (1998).

OTHER INFORMATION

Acronyms

ABN Australian Business Number

ACGIH American Conference of Governmental Industrial Hygienists

ADG Australian Dangerous Goods

AICS Australian Inventory of Chemical Substances

AS Australian Standard

CAS Chemical Abstracts Service (USA)

COC Cleveland Open Cup

EPA Environment Protection Agency (Australian States)

IARC International Agency for Research on Cancer

IP Institute of Petroleum (UK)

NIOSH National Institute for Occupational Safety and Health (USA)

NOHSC National Occupational Health and Safety Commission

(Australia)

NTP National Toxicology Program (USA)

NZS New Zealand Standard

OSHA Occupational Safety and Health Administration (USA)

PEL Permissible Exposure Level

PMCC Pensky - Martens Closed Cup

SCBA Self-Contained Breathing Apparatus

STEL Short Term Exposure Limit

SUSDP Standard for the Uniform Scheduling of Drugs and Poisons

(Australia)

TLV Threshold Limit Valve

TWA Time Weighted Average

UN United Nations

Abbreviations

cP centiPoise

cSt centiStoke

g gram

Hg Mercury

kPa kiloPascal

L litre

m3 cubic metre

mg milligram

mL millilitre

mm millimetre

ºC degrees of temperature in Celsius (Centigrade)

% percent(age)

Note

This form has been prepared in accordance with the National Code of

Practice for the Preparation of Material Safety Data Sheets 2nd Edition

[NOHSC:2011 (2003)] issued by the National Occupation Health and

Safety Commission April 2003.

All information contained in this form is as accurate as possible at the

time of issue. The data contained herein is not to be taken as an

expressed or implied warranty or representation, for which Wynn's

Australia Pty Ltd assumes legal responsibility. No responsibility for

damages resulting from use of the information are given, other than

those implied mandatorily by Federal or State Government

Legislation.

|

|

|

|

Formulated to:

Formulated to: